How did Medit deliver the premium, compact i900 scanner at a midmarket price? In part, by creating sophisticated data processing software that slashed its dependence on expensive componentry.

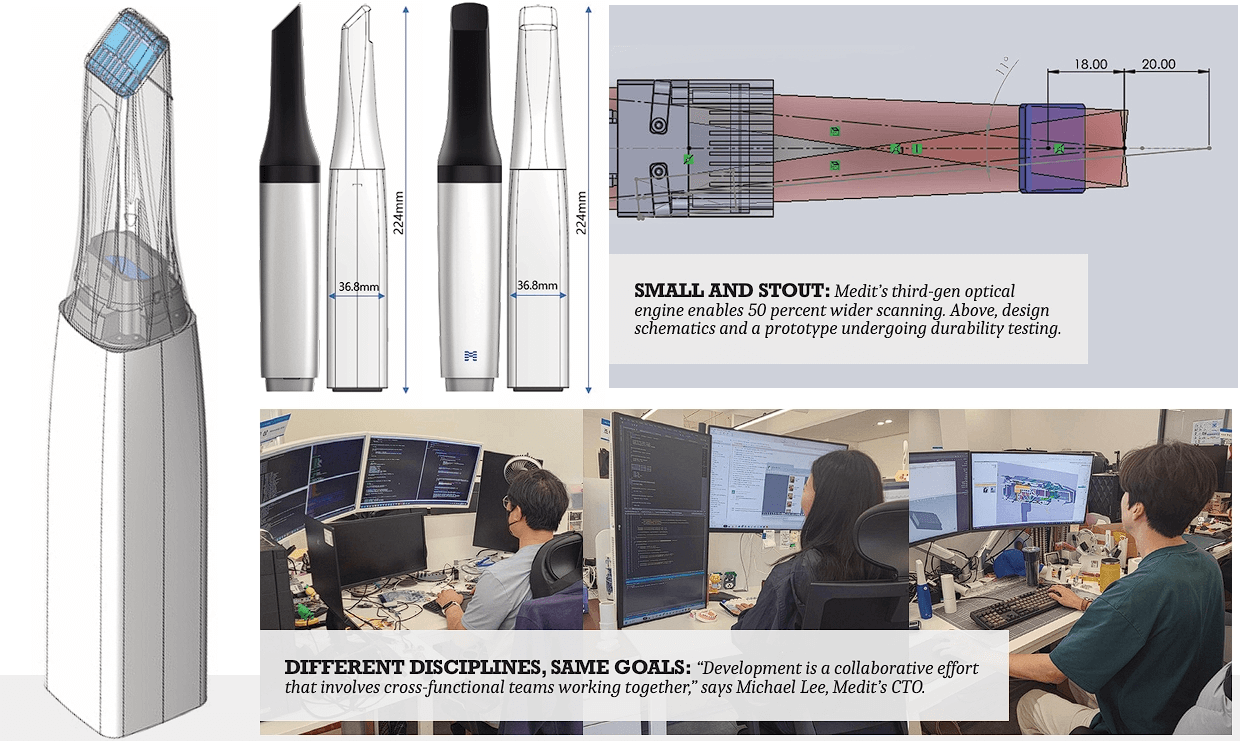

FAMILY EVOLUTION:

The i900 (far left) is Medit’s smallest, lightest scanner to date.

MEDIT MADE A pivotal choice back in the mid-2010s when developing its first intraoral scanner, the i500. According to Michael Lee, the company’s chief technology officer, “The optical triangulation method used by Medit is simpler in design and less expensive in materials compared to the confocal method used by other companies.” The trade-off? “It requires a high level of software-based data processing technology to obtain high-quality data.” It was a good call: The i500 was a huge hit thanks in part to its undeniable bang for the buck.

Fast-forward to today, and Medit has moved significantly upmarket with the new i900. Yet it hasn’t abandoned optical triangulation technology, let alone its reputation for delivering value. “By minimizing hardware dependence to achieve high performance through superior software technology, we are increasing our products’ price competitiveness,” Lee says. Between the development of the i500 and i900, Medit has also “internalized most of the key components and established an efficient supply chain management system,” leaving more money in the product development budget for envelope pushing elsewhere.

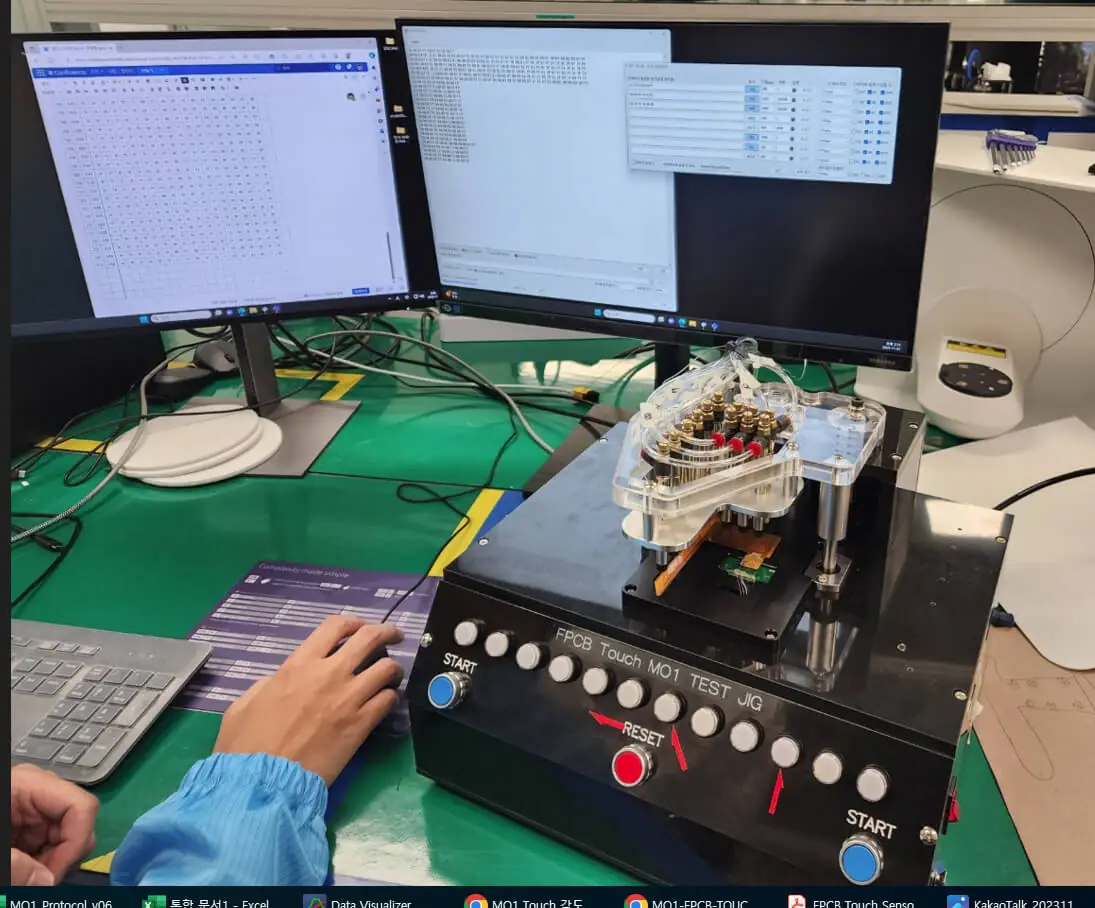

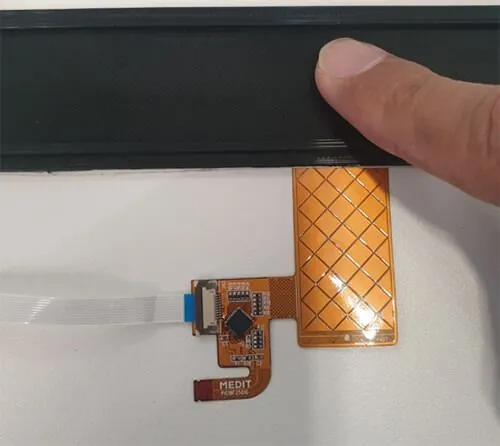

Testing the touch: The i900’s 360° Touch Band underwent rigorous sensor testing and validation.

Better All Around

The i900 is Medit’s highest-priced scanner to date, and Lee knows that means elevated customer expectations. “The holistic experience is important,” he says. To that end, Medit mobilized a development team made up of more than 100 professionals from various departments, including R&D, engineering, product design and marketing. “The marketing team ensures that the product aligns with market needs, while the engineering and design teams focus on integrating cutting-edge technology and user-friendly design.”

Development of the i900 started in 2021 after the release of the i700. (“Typically, a complete hardware redesign occurs on a three-year cycle,” Lee says.) The resulting product is 33 percent lighter and 36 percent smaller, with an improved interface and, most importantly, faster, smoother scanning.

“Industrial design is a critical component of both the market appeal and performance of the i900,” Lee says. “The seamless unibody construction not only provides a sleek, modern aesthetic but also enhances durability by eliminating assembly parting lines where dirt and disinfectants could accumulate.” While it’s more costly to manufacture, and certainly nice to look at, it offers significant benefits in terms of usability and longevity.

Controls . . . and a Cord

You won’t find traditional buttons, or anything like them, on the i900. Instead, what Medit calls a 360° Touch Band enables users

to scan from any angle without adjusting their grip. A quick double-tap anywhere on the band starts or ends the scan, while a swipe right or left allows users to cycle forward or backward in their scanning stages, “reducing fatigue during extended use, which is crucial for maintaining high standards of care,” Lee says.

So why did Medit stick with a cord in today’s increasingly wireless world? Because internal batteries and charging components add cost, heft and complexity that are easily offset by better cable design. “While the i900 is already sufficiently light, what is more important than its lightness is the overall weight balance,” Lee says. “Minimizing the tension pulled by the cable is particularly crucial, so we developed one that is both light and strong. additionally, we optimized the design so that the center of gravity is positioned in the middle of the scanner.” Another plus: The cable can be detached from the body for regular cleaning or easy user replacement.

“The greatest enemy of innovation is familiarity. Medit has not settled for what is familiar but has continuously made bold attempts to lead the market and advance digital dentistry.”

But back to Medit’s optical engine. “It had to meet several conflicting requirements” Lee says, including a wider and deeper scanning range. To that end, it uses one projector but two separate high-speed cameras, which is one more than required for optical triangulation. Combined with 10-bit image processing, it outputs detailed, vividly colored, low-noise scan data.

Sharp reflexes: The i900’s control interface was tested extensively to ensure the finished product responds to every user input.

“Highly reflective metal surfaces, which are typically difficult to scan, can be scanned easier than before, and the 50 percent

wider scanning area allows for faster, more precise scans, enabling anyone to effortlessly scan edentulous arches or dentures,” Lee says. Performance will only keep improving given that, like products from Apple and Tesla, the i900 will receive regular software updates. That’s something the company is especially good at, and users attest to it. Says Lee: “Medit customers feel as though their products are new every year.”

A Job Well Done

Since designing products is like parenting, we asked Lee what he’s most proud of in the i900. Unsurprisingly, it’s not any one thing, but rather, a balance of strengths that enhance the overall scanning experience. “The i900 makes it easy for anyone to achieve exceptional-quality intraoral scans,” offering an experience that “combines the advantages of a wired device with the convenience of a wireless one.” And the next Medit scanner—plus updates to the i900—are already on his mind. “The greatest enemy of innovation is familiarity,” he says. “So far, Medit has not settled for what is familiar but has continuously made bold attempts to lead the market and advance digital dentistry.”