An exclusive look inside Gordon Christensen’s little shop of wonders, in which thousands of devices annually undergo rigorous testing. In come the products, out goes Clinicians Report—the byword for reliable dental assessment. Here’s where it all happens.

An exclusive look inside Gordon Christensen’s little shop of wonders, in which thousands of devices annually undergo rigorous testing. In come the products, out goes Clinicians Report—the byword for reliable dental assessment. Here’s where it all happens.

THE GORDON J. CHRISTENSEN CLINICIANS REPORT has, for the past five decades, been giving promising new medical products the dental version of an IRS audit from its headquarters in Provo, Utah, in the mountains south of Salt Lake City. Though it’s often called “the Consumer Reports of dentistry,” it’s much more than just that. Every year, the Clinicians Report Foundation’s product department receives and purchases tens of thousands of products—from restorative materials to loupes to high-detail imaging tools—from some 3,000 companies worldwide.

Dr. Christensen and his crew don’t do everything on-premises, of course; CR’s team of roughly 40 scientists, clinical evaluators, engineers and support staff select products weekly to send out to their army of field evaluators—a pool of roughly 450 dental clinicians across nearly 20 countries who volunteer to test, review and provide feedback on the goods. That “first level of testing” helps identify the most compelling and outstanding products to receive additional rounds of tests and follow-ups—often as many as three to five years later, says Derek Hein, chief executive of the Clinicians Report Foundation.

The quality of CR’s tests, labs, in-house expertise and the long-term evaluation to which they subject dental devices of all kinds has garnered it an enormous following: some 100,000 subscribers to the monthly digest, and thousands more to its online and in-person continuing-education courses. “There are very few labs doing this level of work,” says Tim Palmer, Clinicians Report’s chief scientific officer. “Especially in dentistry.” Here’s a peek inside.

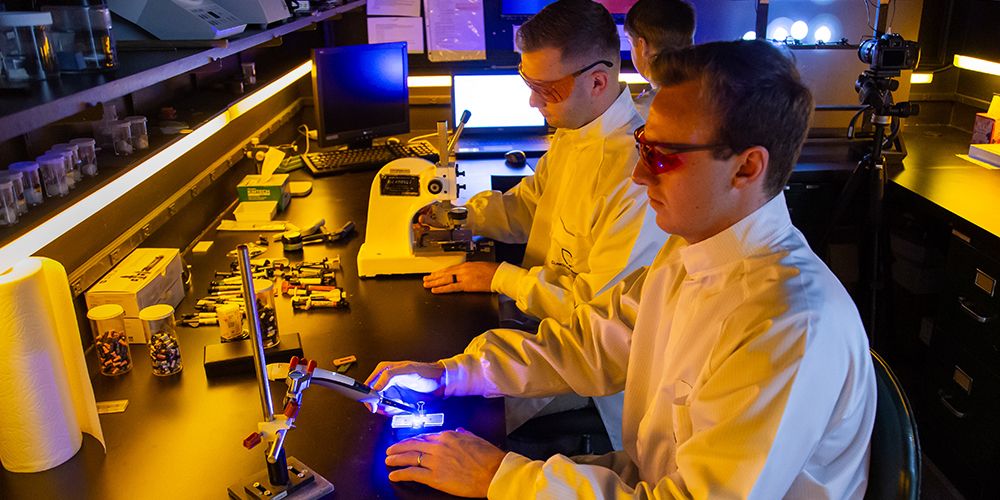

Predental student Cole Christiansen (foreground) tests resin-based composites under a variety of curing lights in a darkroom, while to his right Brian Elison tests the hardness of the resulting polymerization. In the background, Scott Malcom records data from his colleagues’ experiments.

(From left) Practical Clinical Courses instructor Dr. David Wright and three Clinicians Report staffers at a table in the Clinical Studies department full of replica teeth they’re evaluating. “We’re looking at all the new restorative materials and how they perform compared to natural tooth enamel and to some of the highest-performing restorative materials like high noble gold,” Dr. Hein says. “These are replicas made from patients who are being followed [to gauge how their restorations] perform in the oral cavity over time.”

- Kira Standring, a registered dental hygienist and the head of CR’s clinical studies department, hands a detailed replica of a test patient’s teeth to Spencer Perrett, a predental student and part-time CR employee.

- Spencer Perrett prepares a sample of test tooth replicas to observe the long-term performance of dental materials, in particular how they wear down over time in a test patient’s mouth.

- Predental student Cole Christiansen, material science director Chris Howell and predental student Brian Elison use a Keyence LM series digital microscope to measure polymerization shrinkage force with 6061 aluminum jigs. “This is important because it gives dentists a number other than volumetric shrinkage to relate to,” Howell says. “Additionally, it gives a meaningful way to rank composites based on the contractile forces they experience during polymerization.”

- Kira Standring at the microscope; to her left is Zach Yeoman, a predental student and part-time CR staffer.

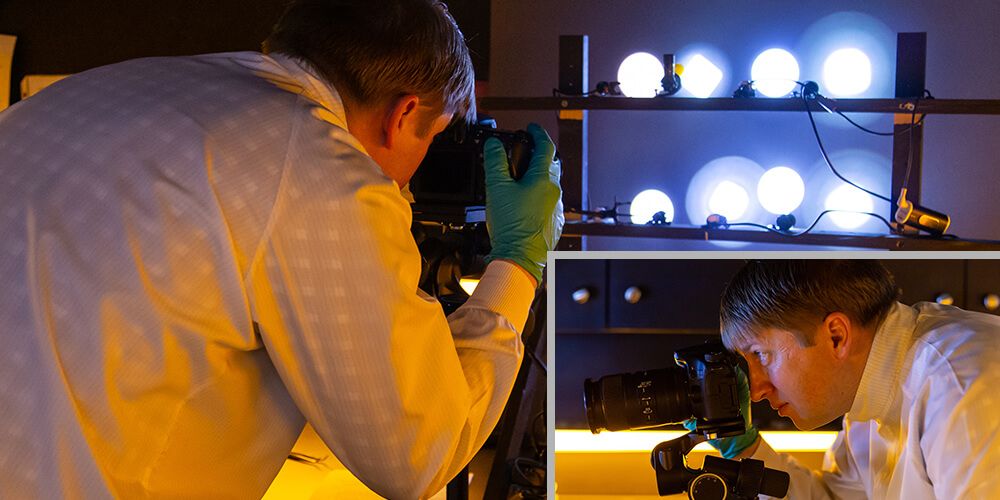

Clinical sciences director Scott Malcom tests dental headlamps to observe which ones’ spotlights have the sharpest edges and the most neutral colors. Headlamps with no fuzzy edges or halos will do a better job of staying out of patients’ eyes, while headlamps that are natural-hued help dentists avoid inaccurate conclusions from what they see. Blueish lights, for example, can make oral tissue look hypoxic, or oxygen-starved.

There are very few labs doing this level of work, especially in dentistry.”

– Tim Palmer

Chief Scientific Officer, Clinicians Report

- Cole Christiansen, Brian Elison and Scott Malcom at the darkroom desk.

- Tim Palmer, CR’s chief scientific officer, evaluates the hydrophilicity of impression materials.

- Dr. Gordon Christensen (left) and Dr. Mark Durham, a prosthodontist and associate professor at the University of Utah School of Dentistry, along with Dr. David Wright, examine a pair of flip-up loupes CR’s product department plans to send to practicing dentists for field evaluation. “About 80 percent of the products fall short of their manufacturer’s claims in that first round of testing,” Derek Hein observes. “This helps us focus in on those they find are unique, outstanding and noteworthy.

Dr. Rella Christensen (middle), cofounder of the Clinicians Report Foundation and head of TRAC Research (clinical studies of preventive restorative materials and dental caries); administrative assistant Kaesy Barker; and virologist Brad Ploeger study charts identifying the various organisms (and their quantity) that they’ve spotted in a specific cavity. “You’re seeing very high-level microbiology here to actually collect organisms from a living patient, grow them both aerobically and anaerobically, then do DNA sequencing—there are very few labs, especially in dentistry, doing this work,” says CR chief scientific officer Tim Palmer.

- Scott Malcom examines a restoration undergoing a long-term crown study, looking for large defects. It will subsequently be examined via scanning electron microscope to study degradation of the material itself.

- Colette Hansen, a dental assistant in Clinicians Report’s product department, keeps in regular contact with the dental companies that send CR sample products to evaluate.

(Right, from left) Scott Malcom, CR’s clinical sciences director; Kira Standring, a registered dental hygienist and head of CR’s clinical studies department; Derek Hein, CEO of CR; Tim Palmer, chief scientific officer; Dr. Mark Durham, associate professor and holder of the Dr. Gordon and Rella Christensen presidential endowed chair at the University of Utah; Dr. Gordon Christensen; Chris Howell, material science director; Valinda Johnston, CR board member and lead assistant to Dr. Christensen; and Dr. David Wright, an instructor with Practical Clinical Courses.

- Dr. Gordon Christensen, Amanda Johnson and CR board member Valinda Johnston, chairside for an ongoing experiment.

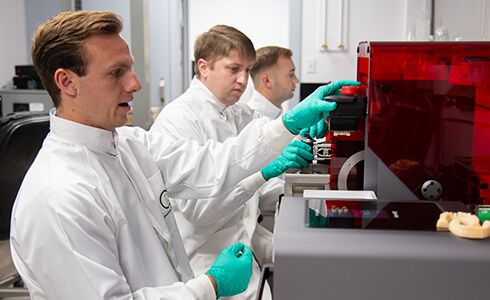

- Cole Christiansen (foreground), a predental student currently doing his surgical dental residency, examines the quality of new crowns on the build platform of a 3D printer. Scott Malcom (middle) and Brian Elison help with the evaluation.

Dr. Gordon Christensen treats patient Amanda Johnson with a restorative material, such as a composite resin for a filling, that CR intends to study. Johnson, who handles mailings and leads the Clinicians Report production department, will be examined many times in the coming years so the CR doctors can study how the restorative material in her mouth has changed over time. Dr. Christensen is accompanied by Valinda Johnston and Cole Christiansen.

Photography by Erica Rascon: ericarasconphotography.com

An exclusive look inside Gordon Christensen’s little shop of wonders, in which thousands of devices annually undergo rigorous testing. In come the products, out goes Clinicians Report—the byword for reliable dental assessment. Here’s where it all happens.

An exclusive look inside Gordon Christensen’s little shop of wonders, in which thousands of devices annually undergo rigorous testing. In come the products, out goes Clinicians Report—the byword for reliable dental assessment. Here’s where it all happens.